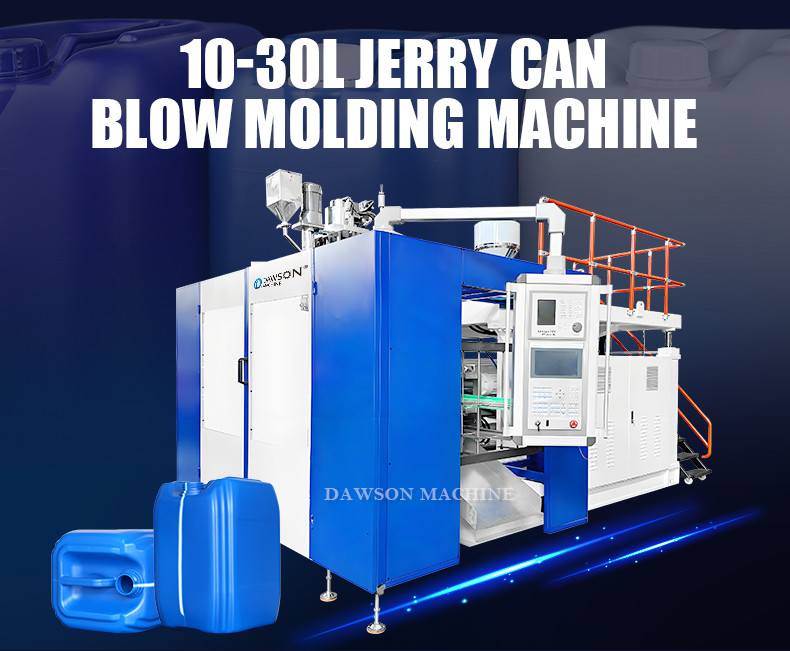

The 20L 25L Single Station Single Die Head Extrusion Blow Molding Machine stands as a remarkable piece of industrial equipment, embodying a perfect blend of advanced technology and practical design. This machine is specifically engineered to meet the diverse needs of the manufacturing industry, offering high - quality production capabilities for a wide range of plastic products with volumes of 20 liters and 25 liters.

At the heart of this extrusion blow molding machine lies its powerful extrusion system. Driven by a high - torque AC motor, the extrusion process is both efficient and reliable. The AC motor provides consistent power, ensuring a smooth and continuous flow of molten plastic through the extrusion barrel. The extrusion barrel itself is constructed from high - grade alloy steel, which offers excellent heat resistance and durability. It is equipped with multiple heating zones that can be precisely controlled. These heating zones allow operators to fine - tune the temperature of the plastic material at different stages of the extrusion process. By maintaining the optimal temperature, the quality of the extruded parison (the tube - like structure from which the final product is formed) is significantly enhanced. The precision temperature control also reduces the likelihood of material degradation, minimizing waste and improving overall production efficiency.

The single die head of the machine is a key component that contributes to its outstanding performance. The die head is designed with advanced flow channels and a precisely engineered orifice. These features ensure an even distribution of the molten plastic as it exits the die, resulting in a uniform - walled parison. The die head can be easily adjusted to change the diameter and thickness of the parison, providing the flexibility to produce different types of products. For example, when manufacturing containers with different shapes and sizes, operators can quickly modify the die head settings to achieve the desired parison dimensions. This adaptability makes the 20L 25L Single Station Single Die Head Extrusion Blow Molding Machine suitable for a variety of applications, from producing standard cylindrical containers to more complex and customized shapes.

The single - station design of the machine offers several advantages. It simplifies the production process, reducing the complexity and potential points of failure compared to multi - station machines. This simplicity also makes the machine easier to operate and maintain. The single station is equipped with a high - precision clamping unit. The clamping unit uses hydraulic power to securely hold the mold in place during the blow - molding process. The hydraulic system provides a strong and consistent clamping force, ensuring that the mold remains tightly closed and preventing any leakage of the molten plastic. This not only guarantees the integrity of the final product but also enhances the safety of the operation. The clamping force can be adjusted according to the requirements of different molds and products, providing further flexibility in the production process.

In terms of automation, the machine is integrated with an advanced PLC (Programmable Logic Controller) system. The PLC system controls and monitors all aspects of the machine's operation, from the extrusion speed and temperature to the clamping and blowing processes. Operators can input production parameters through a user - friendly touch - screen interface. The PLC system then automatically adjusts the machine's settings to ensure optimal performance. It also has built - in diagnostic functions that can quickly detect any malfunctions or errors in the system. This allows for timely maintenance and reduces downtime, keeping the production process running smoothly. Additionally, the machine can be connected to a factory's central control system, enabling remote monitoring and management, which further improves overall production efficiency and productivity.

The machine also features an efficient cooling system. After the blow - molding process, the newly formed plastic products need to be cooled rapidly to maintain their shape and quality. The cooling system consists of a series of cooling channels integrated into the mold and an external cooling unit. The cooling channels are strategically designed to ensure even heat dissipation from the product. The external cooling unit, which can be either air - cooled or water - cooled depending on the specific requirements, provides a continuous supply of coolants to the cooling channels. This rapid and uniform cooling process not only shortens the production cycle but also improves the surface finish and dimensional accuracy of the final products.

In conclusion, the 20L 25L Single Station Single Die Head Extrusion Blow Molding Machine is a highly sophisticated and versatile piece of equipment. With its powerful extrusion system, precise die head, efficient single - station design, advanced automation, and effective cooling system, it offers manufacturers a reliable and efficient solution for producing high - quality plastic products in the 20 - liter and 25 - liter range. Whether it's for the packaging industry, household products, or industrial applications, this machine is capable of meeting the most demanding production requirements while maintaining excellent product quality and production efficiency.